Air Blow Guns

Cromwell's versatile range of blow guns are designed for use throughout a wide range of industries and applications. Here's a comprehensive guide detailing what they are, when they're used, and the key considerations when purchasing an air blow gun.

Cromwell stocks a large range of quality blow guns and nozzles, available in a variety of styles and configurations to suit any job.

What are blow guns?

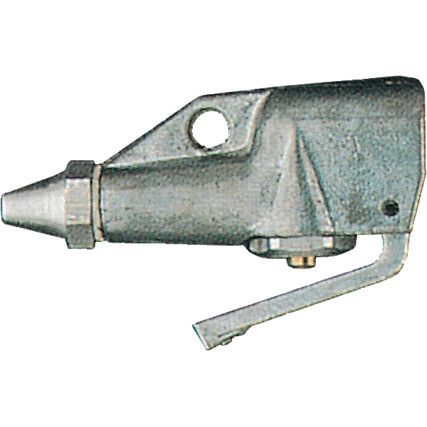

Blow guns are fairly simple devices that use compressed air to project a strong flow outward. In terms of looks, they both look and operate in a similar way to a standard gun. Most have a large trigger-handle that users can squeeze to control the flow of air through the nozzle and have the functionality to shut off automatically when dropped thanks to an internal fail-safe mechanism.

Why a blow gun?

Some industries require clean surfaces to keep things working effectively or to avoid contamination. This includes hair, dust, or tiny fibres that may be missed by other cleaning methods.

By using a powerful air stream to leave surfaces meticulously clean, blow guns are one of the very few cleaning methods that don't involve contact or chemicals. This makes them incredibly safe to use and suitable for use in places where contamination can cause major issues, such as the food packaging industry.

When are blow guns used?

Connected to a powerful line of compressed air, blow guns produce a strong jet-stream of air that can be used to quickly clear and clean parts and surfaces. Blow guns have a range of uses, including:

• Non-contact cleaning

• Drying

• Debris removal

• Cavity cleaning

This makes blow guns a necessary addition for effective work in:

• Manufacturing plants

• Workshops

• Laboratories

• Factories

• Car body shops

Types of blow gun

With most air blow guns utilising the same type of design, your main choice lies within the type of nozzle you buy for your blow gun. The different nozzles direct the compressed air in unique ways, with each nozzle typically specialised to a specific usage.

• Straight nozzle - The standard nozzle type, provides constant and consistent pressure.

• Safe straight nozzle - Similar to a regular straight nozzle, but with side openings that act as pressure regulators. This is useful for preventing damage.

• Star shaped coanda - The star shaped coanda has a central cone-shaped nozzle with a few side openings to help with air flow. Coanda nozzles excel at drying and cavity cleaning.

• High flow coanda - Similar to the star shaped Coanda but with a much larger central diameter. This allows much more air through, and several openings on the side of the nozzle help amplify air pressure.

• Flat nozzle - Flat nozzles are suitable for fanning out air over large areas and excel and drying out bigger parts and areas in less time.

• Venturi nozzle - Venturi nozzles have much larger side openings, allowing more natural air in whilst using less compressed air. This results in more efficient use but less overall thrust.

If you're looking for personalised recommendations on the right type of blow gun nozzle for your job or application, ask our experts for specialised advice.

Considerations when buying blow guns

• Material - Air blow guns are typically available with a plastic or metal design. Metal blow guns are more durable and reliable, yet most professionals prefer plastic blow guns. This is because plastic blow guns are much lighter, and the cold airflow makes metal blow guns very cold to hold. This is much less of a problem with a plastic handle.

• Protection - Many blow guns now come with protective shields. This is to help prevent small debris projected into the air by the blow gun to enter the users eyes or lungs, however face masks and suitable eye protection is still highly recommended - even with a protective shield.

• Operation - Blow guns generally have two types of flow control - a pistol grip or a control knob. Pistol grips work like a gun, where the user controls flow based on how far the trigger is pulled. This is generally easier and more straightforward to use than a control knob, which cannot be adjusted as easily on the fly. However, control knobs allow for more precision when controlling the air flow.

Blow gun jargon buster

Safety standards:

When used without proper knowhow, blow guns can be dangerous to users and parts alike. Whilst there is no specific regulation regarding the blow gun itself, there are laws and standards surrounding the proper usage of a blow gun. In the USA and EU countries, all air blow gun usage should meet the following regulations:

• OSHA 29 CFR: Part 1910.242b - compressed air shouldn't be used for cleaning unless air pressure is under 30psi.

• Management of Health and Safety at Work Regulation 1999 - Air blow guns should only be used with effective safety equipment, including eye protection. A risk assessment must be carried out before use.

FAQ

What size air compressor for blow gun?

Air blow guns have relatively small pressure chambers designed to force air out at high pressure. We recommend an air compressor that can run a minimum of 3,000PSI for blow guns, although air compressors that can achieve higher PSIs may yield better results.